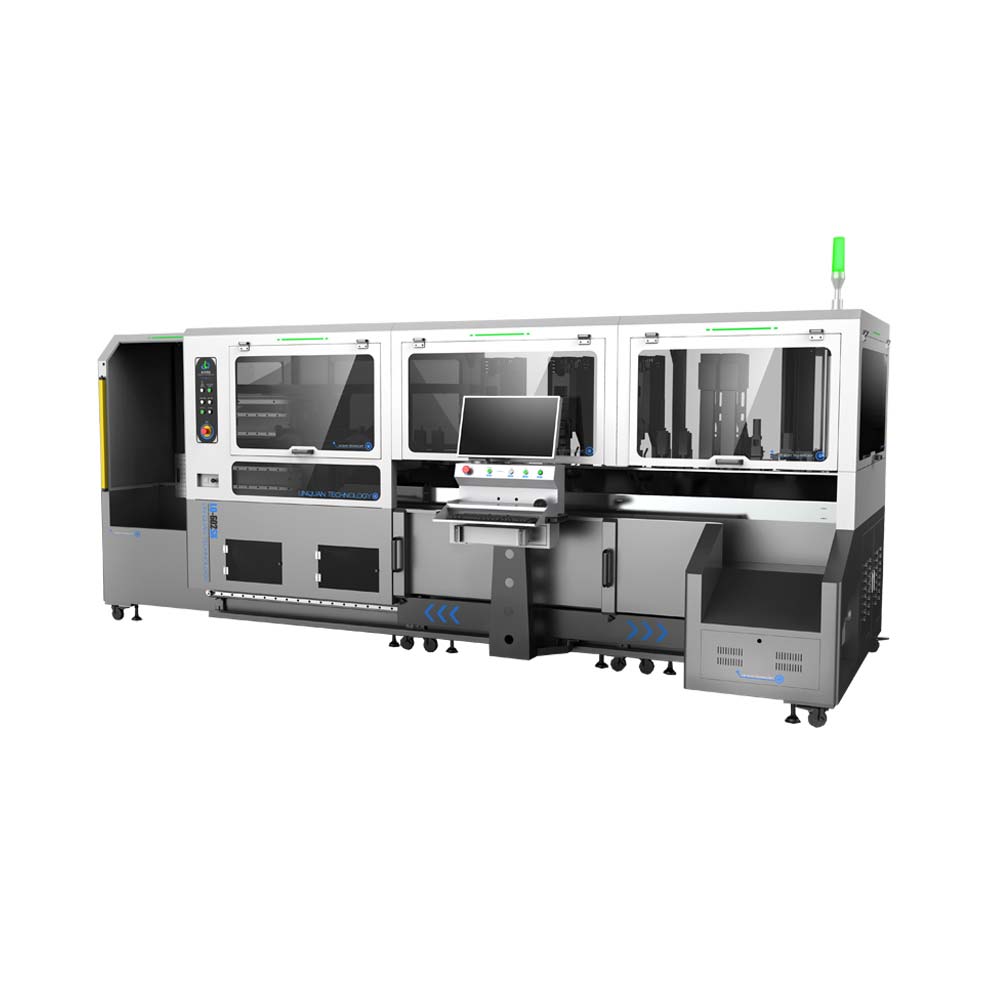

LOONG-860C(602SX)

龙系列线束制造设备可以生产不同复杂程度的线束。

具有两端切割、两端剥皮、两端压接、两端插入等功能。

能够显著缩短生产时间,有效减少生产成本。

模块可定制,可根据需要选择3个或12个模块。

技术参数

| 电线尺寸 | 0.13mm²-2.5mm² | 送线长度 | 280-9999mm |

| 功率 | 10KW | 气压 | 0.5Mpa |

| 电源 | 3 相 380V/50HZ | 切断精度 | 设定切断长度*0.02mm |

| 剥皮长度 | 全剥: 0-15mm 半剥: 0-15mm | 剥皮切入深度 | 最大调整量 3mm |

| 选线器 | 可供最多50种颜色、线径线材 | 同时容纳胶壳种类 | 30种胶壳 |

| 存线盘 | 30组存放位置 | 产能 | 两端压着两端插胶壳约1000根/H(根据加工条件不同,速度略有不同) |

| 模具装配类型 | 装配AS40型、AS42型、AE30型(气动模具可定制) | 压接能力 | 3T 注:最大电机扭矩,非额定扭矩,且需要特定设定才能达到 |

| 质量检测内容 | 电线有无、电线过载、端子有无、端子过载、剥皮画像检测、接头检测、端子压着画像检测、压力检测、插拔力检测 | 集成质量检测单元 | CCD视觉检测,CFM压力检测传感器,插入里/拉拔力检测传感器,端子压接高度测试仪,端子压接拉拔力检测仪 |

| 设备功能 | 两端定长切断、剥皮,两端压着、两端插入、显示屏调节压着高度、不良品CCD在线检测选别排出 | 可选功能 | 林全MES系统、激光喷墨、穿防水栓、拧线沾锡、绞线、合压、双压、最高12组压接机头、胶壳上料模式:流转载盘/条形治具 |

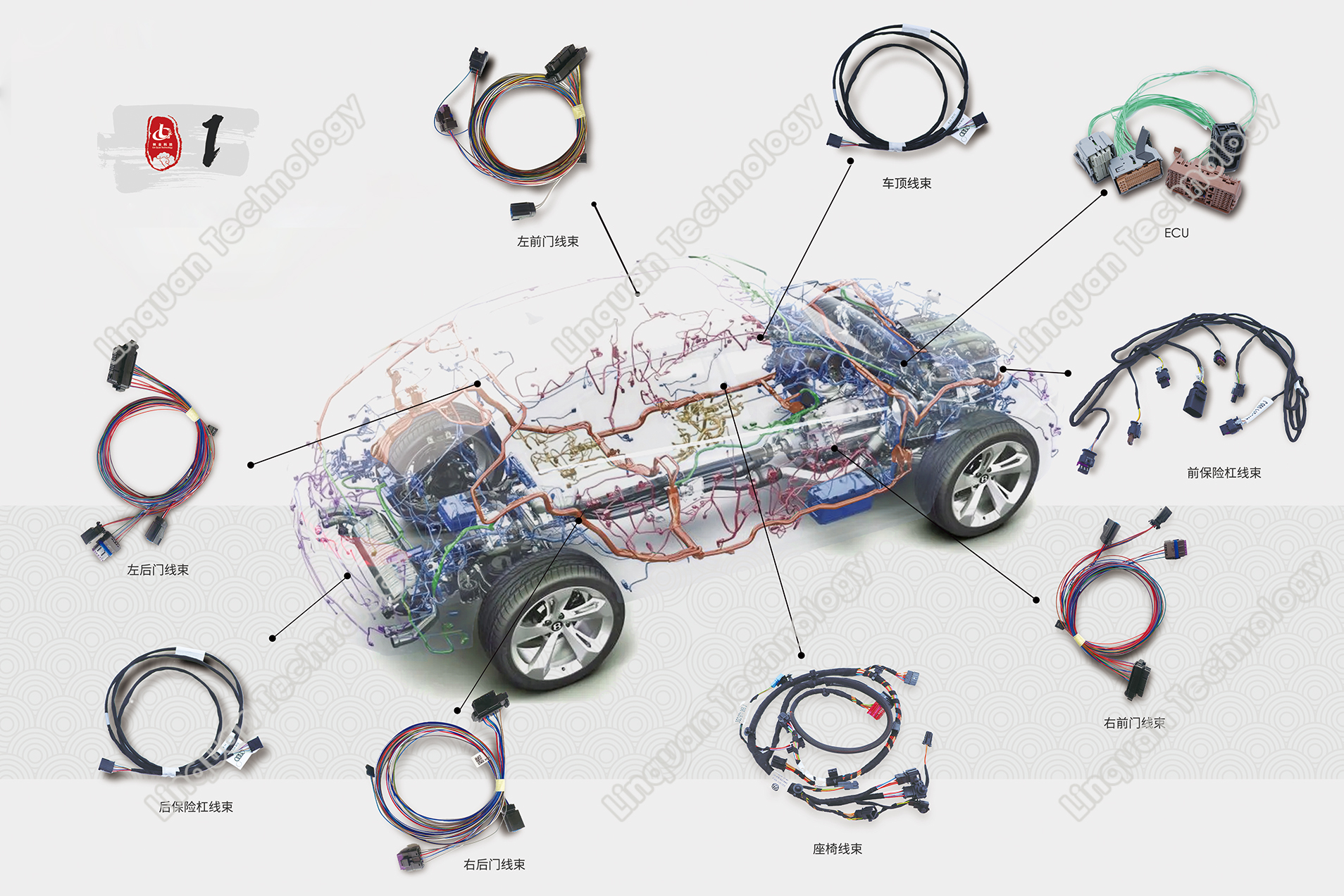

汽车线束自动化生产

Loong-860C平台是一款为解决电线插入塑胶连接器而设计的智能线束加工中心,得益于颠覆性的自动化设计理念和多年的塑件插接领域的经验积累,林全Loong-860C平台完美的满足线束生产中各个核心工艺以及严格质量控制等要求,以创新的自动化解决方案最大限度的替代了传统线束生产中离线存储,人工搬运,人工插接分段式生产模式,重新定义了下一代汽车线束加工流程。

-

保证长效的数据可追踪性。

-

出色的人性化操作界面设计。

-

高柔性模块化组合,快速且简易换型流程。

-

高效的全自动插接工艺兼容多种线束生产模式。

-

标配出多重嵌入式质量检测系统,具有自主知识产权视觉检测和压力检测单元,确保持续且稳定的质量监控。

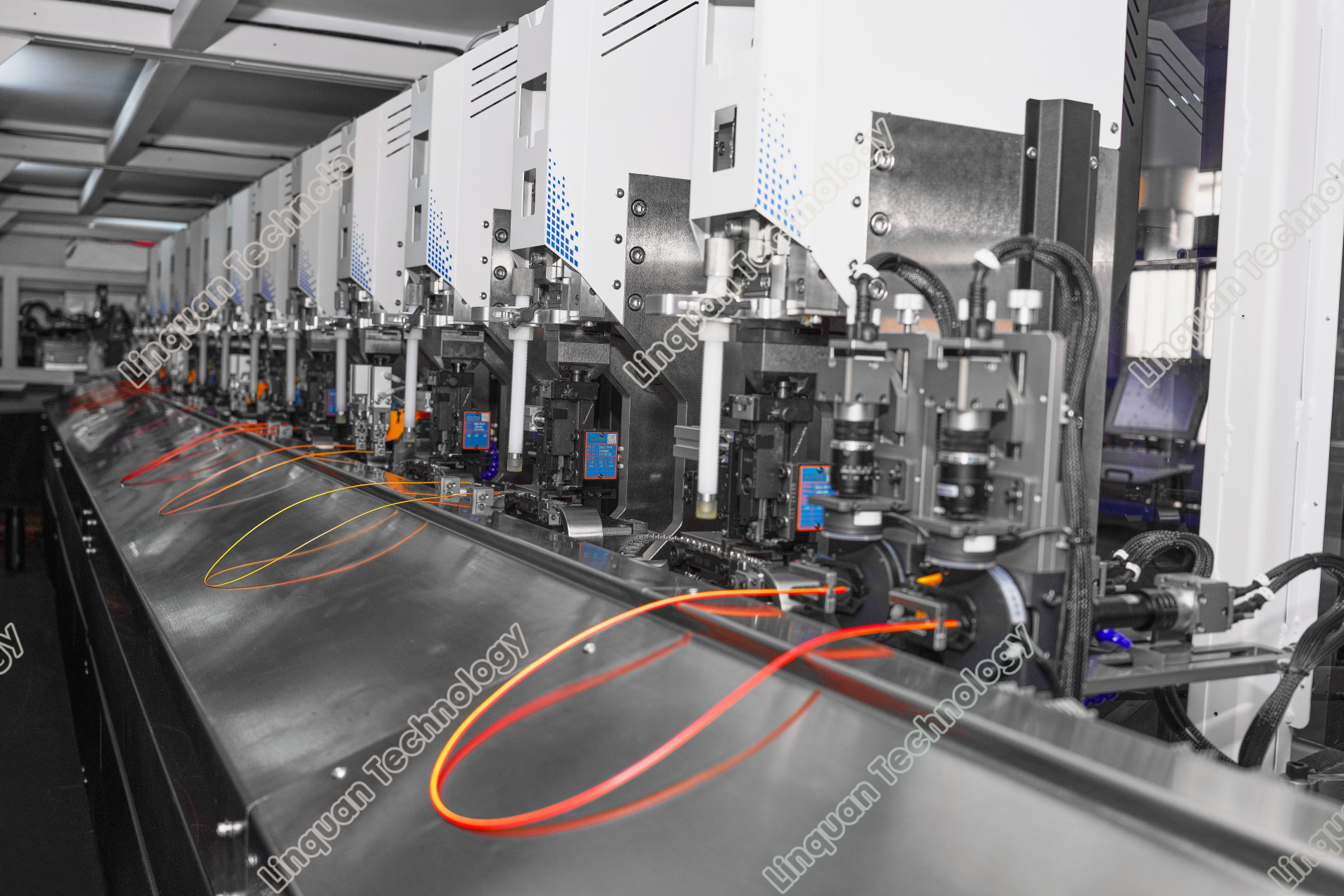

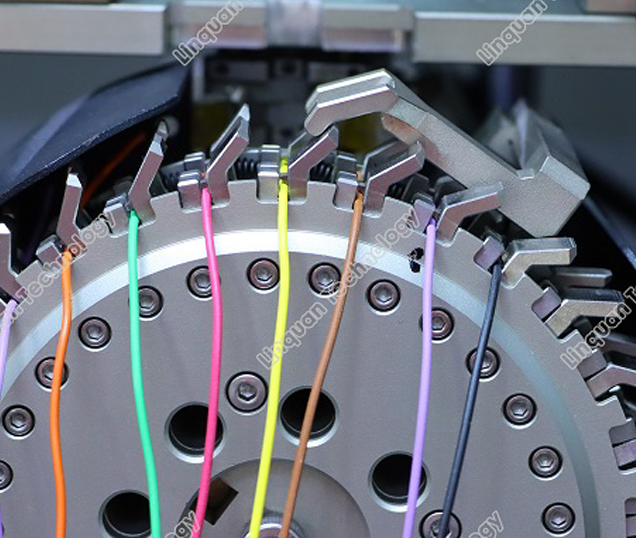

压接模块(C202)

伺服驱动压接机构,压接精确且稳定集成化CFM压力检测器,精准检测每次压接力度,适用于多种压接高度。

根据需求灵活配置压接模块数量,一台设备最高可配备12组压接工站。

可通过操作界面轻松调节压接高度。

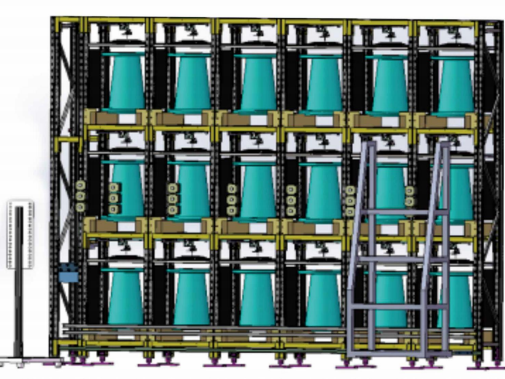

送线墙

立体式送线机构可兼容多组线轴存放,大量节省生产空间。

选线器

可兼容最高50组不同线径不同颜色线缆。

简单,快速更换0.13-4.0mm²(AWG26-11)穿线管,以适用于不同产品生产。

消除打拧机构

矫正送线时经常出现的交叉打拧现象消除加工隐患,提高良品率。

切断剥皮模组

采用三对高速钢化切刀(V型切刀/R角切刀)。

通过操作界面快速调整切断剥皮参数值使切断剥皮高度精确且切面整齐。

可以提前在操作界面存入对应剥皮参数同时加工多种线径线缆节省换型时间。

CCD视觉检测(TDVM-1)

一体化质量监控模块,对剥皮、压接、芯线实施高效检测。

实时检测可立即发现不良品且进行处理避免影响生产效率。

防水栓工站(STA201)

Loong-860C 最多可同时兼容6组防水栓工站。

新一代防水栓工站具有小巧的外型及最优化的结构设计,可适配多种不同防水栓加工需求。

林全自主研发创新型防水栓送料机构S201中央供料机。

独立型供料设备可高效不断为多台线束加工中心的防水栓工站供料。

每台防水栓中央供料机可最多搭载4组A201防水栓大配套及8组M201防水栓弹夹。

灵活的防水栓弹夹设计方便组装替换,大幅节省换型时间。

防水栓中央供料机(S201)

存线盘

30组存线结构,大幅优化插入顺序。

遵从左到右、下到上的插入顺序避免线缆因不合理顺序导致无法插入胶壳。

专为系列型整套复杂线束设计的结构。

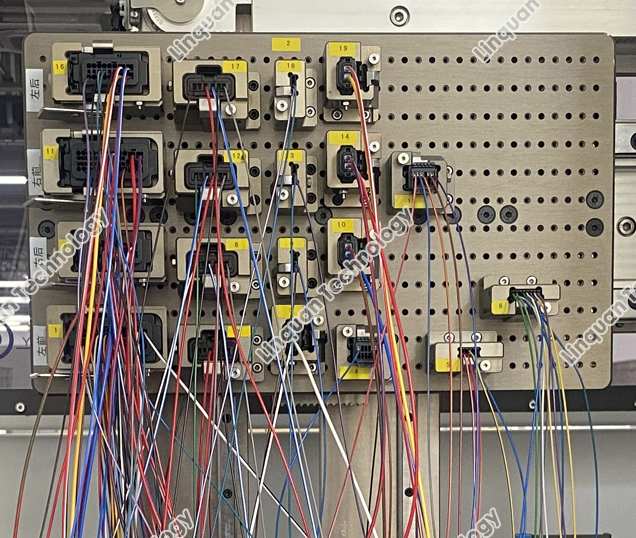

插入夹

独特前后双夹设计,保证插入稳定性,准确性和高效性。

多段式插入,确保端子插入到位。

集成式拉拔力检测确保线缆成功且牢固插入连接器。

流转载盘胶壳上料机构

配备两块载盘交替上料,可同时容纳多种不同连接器。

可通过简易换型生产多套线束。

方便快捷的人工上下料设计。