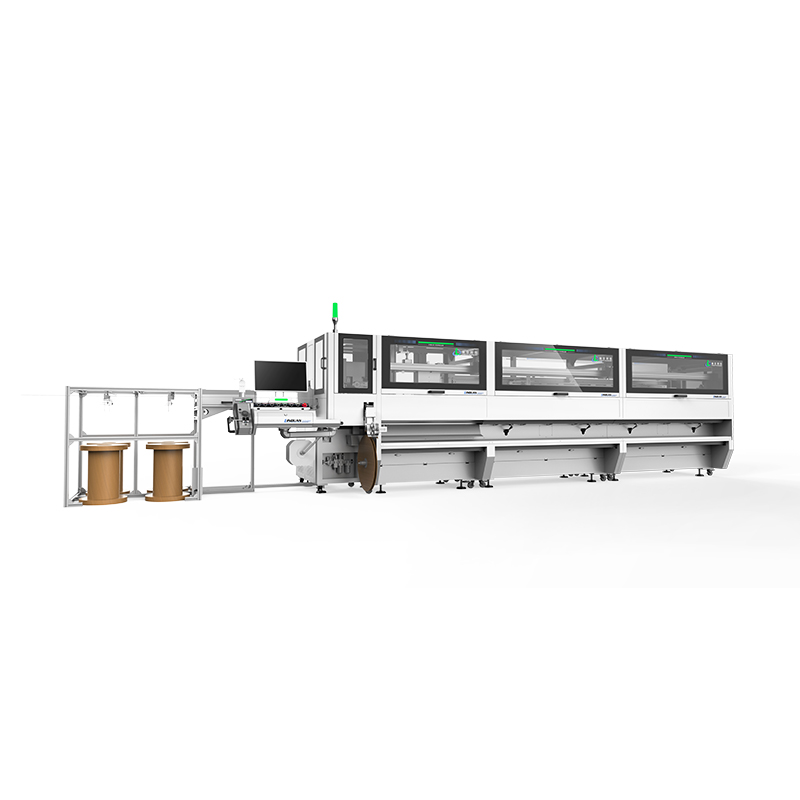

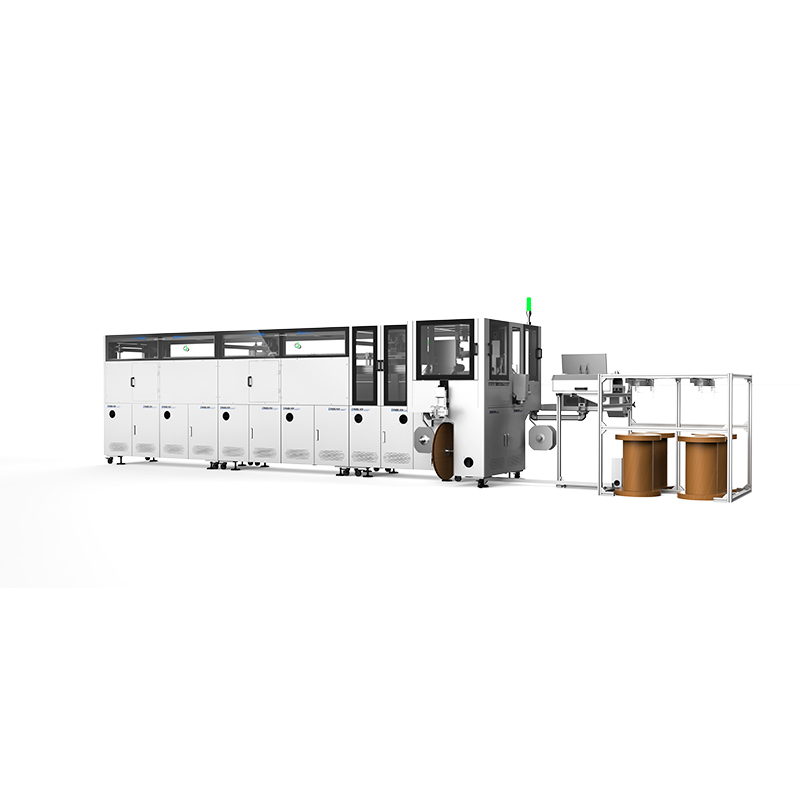

TIGER-60T

Equipment Function

Both-end Conveying, fixed length Pull the line,fixed length cutting, both-end stripping,both-end seal station, both-end crimping, twisted two wires, both-end wrap tape,automatic adjustment of crimping height, terminal NG cutting, unloading defective products through CCD inspection

Technical Parameters

| Wire Cross-section | 0.13mm² - 2.5mm² (AWG26-AWG13) | Power | 20 kW |

| Min. Length | 360mm | Stripping Length | 0-15mm±0.1mm(feed blade precise to 0.01mm) |

| Wire Feed-in Speed | 3m/s | Feeding Accuracy | ±(0.2% * L+ 1.0 mm) |

| Crimping Capacity | Rated torque output: 1.2t @ 180° rotation, 3t @ 360° rotation. | Power Source | 220V/ 3Phase/ 50-60 Hz |

| Opening Size | 30-90mm | Twisted Pitch | 5~80mm |

| Compressed-air Connection | 0.5-0.7Mpa | Optional | Linquan MES system, seal station |

| Dimension(mm) | L8,600 * W2,800 * H1,800 | Weight | ≈3,500kg |

| QC Devices | CCD inspection, crimping force monitoring (force sensor), terminal crimping height measuring instrument, terminal pull-back force measuring instrument | QC Contents | Wire presence, wire overload, terminal presence, terminal overload, stripping visual inspection, terminal crimping visual inspection, crimping force inspection, twisted wire tensile force inspection |

| Functions | Both-end Conveying, fixed length Pull the line,fixed length cutting, both-end stripping,both-end seal station, both-end crimping, twisted two wires, both-end wrap tape,automatic adjustment of crimping height, terminal NG cutting, unloading defective products through CCD inspection | Efficiency | Both-end crimping1,200 -1,500 sets/h of twisted wires (The speed is a bit different according to different processing wire length) |

| Parameters are indicative and may vary by product type. Our engineering team will review your specific needs and ensure the best solution. | |||