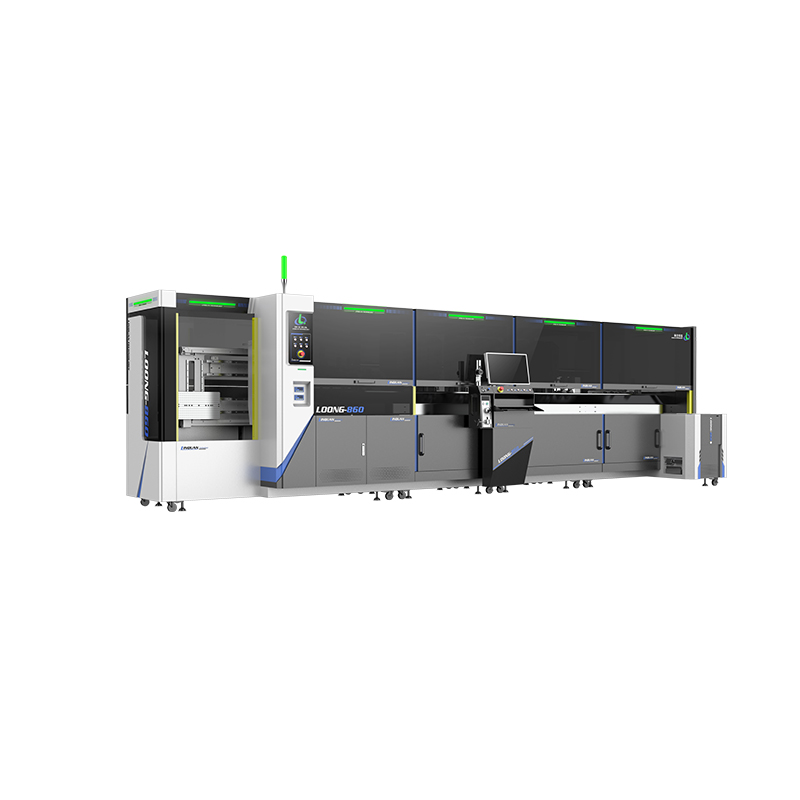

LOONG-860E (6 crimping modules)

The Loong Series Harness Manufacturing can produce more wire harnesses of varying degrees of complexity.

It has the functions of Both-end measuring cutting, Both-end striping, Both-end crimping, Both-end Insertion and so on.

Reduce production time significantly.

3 or 12 modules can be selected, as required.

The Loong Series is a better choice for miniaturization and increasingly smaller batches.

These machines make it possible to manufacture a range of different wire harnesses.

Technical Parameters

| Wire Cross-section | 0.13mm² - 2.5mm² (AWG26 - AWG13) 1mm² - 4mm² (AWG17 - AWG11) | Stripping Length | 0-25mm±0.1mm (feed blade precise to 0.01mm) |

| Wire Selector | max. 50 wires | Feeding Accuracy | ±(0.2% * L+ 1.0 mm) |

| Min. Length | 200mm | Max. Length | 9999mm |

| Crimping Capacity | Rated torque output: 1.2t @ 180° rotation, 3t @ 360° rotation. | Raw Material Error-proofing | Error proofing of wire, seal, terminal, applicator, connector by code scanning |

| Power Source | 220V / 3 Phase / 50-60 Hz 380V / 3 Phase / 50-60 Hz | QC Contents | wire overload, terminal overload, stripping visual inspection,visual inspection of the number of core wires, terminal crimping visual inspection, crimping force inspection, insertion force inspection, pull back force inspection, ACD injury core wire inspection |

| CT | 2.5-3.5s/pc | Wire Feed-in Speed | 0-6m/s |

| Power | 25kW | Noise Level | ≤75dB |

| Wire Storage | 30 storage sites | Compressed-air Connection | 0.5-0.7Mpa |

| Fixture Pallet Dimension(mm) | 430mm * 260mm | Optional | visual inspeciton of terminal angle, terminal NG cutting, product labeling, Lin Quan MES system, seal station, number of presses can be increased |

| Weight | 4800kg | Dimension(mm) | L7200 × W2280 × H2290 (6 presses) |

| Functions | wire presence status, terminal presence, automatic feeding, fixed length cutting, both-end stripping, both-end crimping, both-end inserting, automatic adjustment of crimping height, unloading defective products through CCD inspection,scan code to match, production data storage | Production Data Traceability | wire length, stripping length, core wire inspection photo, terminal appearance inspection photo, crimping force data, insertion force data, pull-back force data, product processing information |