LOONG-860E(3 crimping modules)

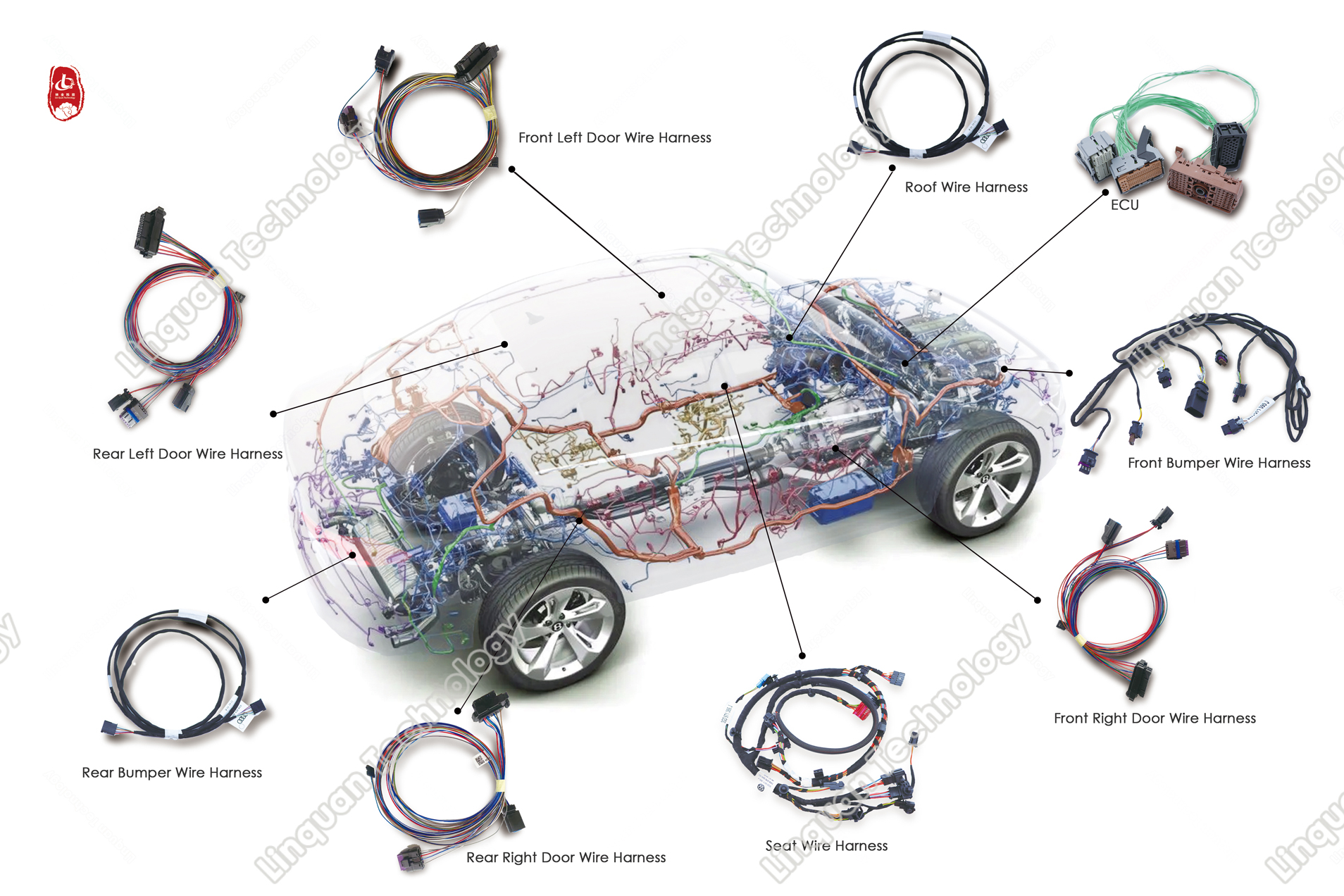

The Loong Series Harness Manufacturing can produce more wire harnesses of varying degrees of complexity.

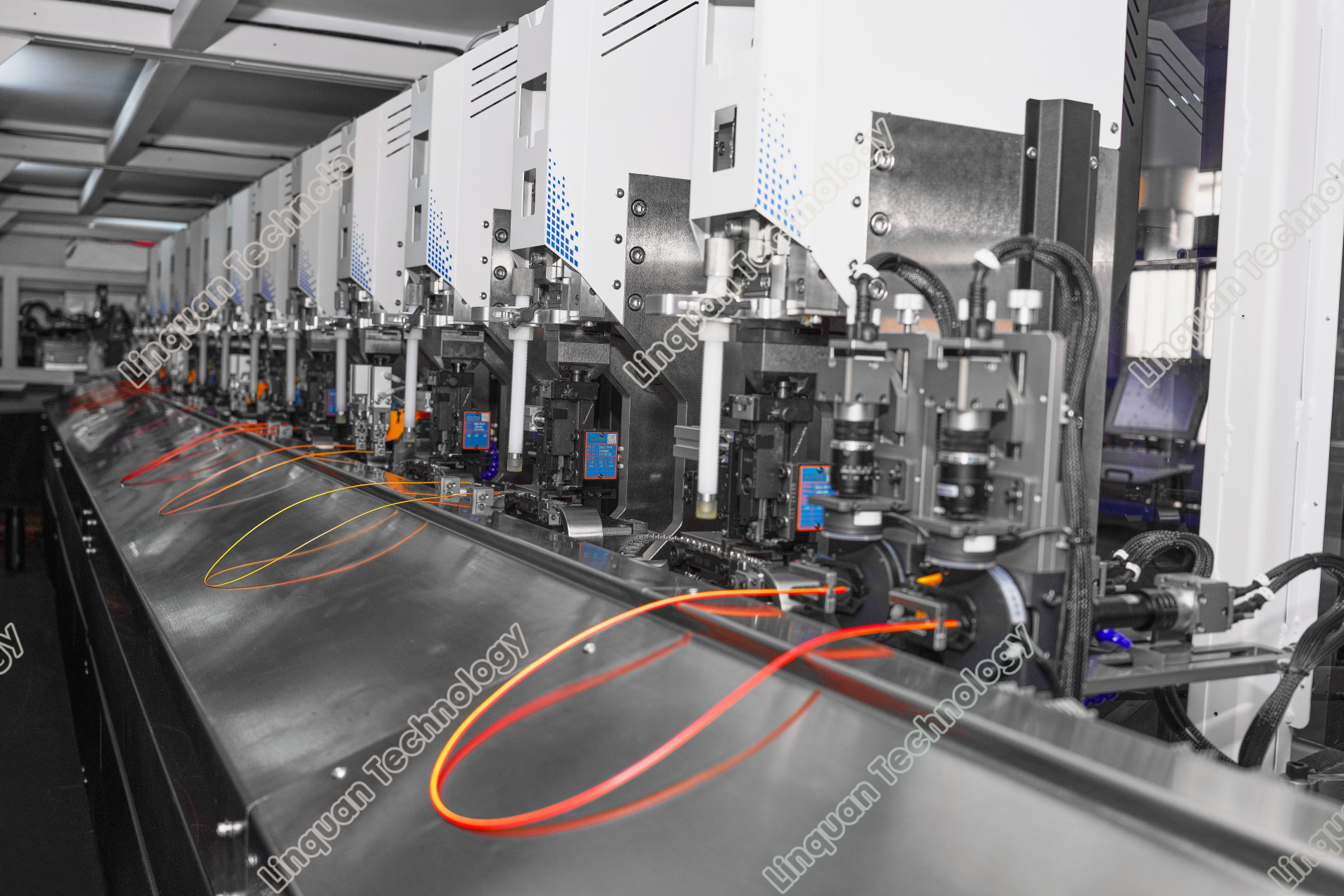

It has the functions of Both-end measuring cutting, Both-end striping, Both-end crimping, Both-end Insertion and so on.

Reduce production time significantly.

3 or 12 modules can be selected, as required.

The Loong Series is a better choice for miniaturization and increasingly smaller batches.

These machines make it possible to manufacture a range of different wire harnesses.

Technical Parameters

| Wire Cross-section | 0.13mm²——4.0mm² (AWG26-AWG11) | Stripping Length | 0-25.00mm±0.1mm (feed blade precise to 0.01mm) |

| Min. Length | 200mm | Max. Length | 9999mm |

| Cutting Precision | ±(0.2% *L+ 1.0 mm) | CT | 2.2-3.0S/pc(1.1-1.5s per hole) |

| Insertion Pass Rate ( calculated by cavity ) | 99.95% | Wire Feed-in Speed | 0-6m/s |

| Changeover Time | 1 Min. | Wire Selector | max. 50 wires |

| Fixture Pallet Dimension(mm) | 430mm * 260mm(capacity: approx. 30 connectors) | Power Source | 220V / 3 Phase / 50-60 Hz 380V / 3 Phase / 50-60 Hz |

| Power | 35KW | Noise Level | ≤75dB |

| Compressed-air Connection | 0.5~0.7Mpa | Crimping Capacity | 3 Tconditions for achieving maximum crimping force: maximum motor torque adopted and specific settings applied |

| QC Contents | wire overload, terminal overload, stripping visual inspection,visual inspection of the number of core wires, terminal crimping visual inspection, crimping force inspection, insertion force inspection, pull back force inspection, ACD injury core wire inspection, visual inspeciton of terminal angle | Production Data Traceability | wire length, stripping length, core wire inspection photo, terminal appearance inspection photo, crimping force data, insertion force data, pull-back force data, product processing information |

| Raw Material Error-proofing | Error proofing of wire, seal, terminal, applicator, connector by code scanning | Functions | wire presence, terminal presence, automatic feeding, fixed length cutting, both-end stripping, both-end crimping, both-end inserting, automatic adjustment of crimping height, unloading defective products through CCD inspection, terminal NG cutting, scan code to match, production data storage |

| Dimension(mm) | L5545*W1957*H2070 | Weight | ≈7000KG |

| Optional | product labeling, Lin Quan MES system, seal station, number of presses can be increased, connector loading mode: pallet switching |

The loong 860 is designed for one-stop,lean manufacturing of complex wire harness with less middle storage and less operator engagement. Thanks to robust automated design and outstanding degree of flexibility, Loong-860 could easily adapt both sequence and batch production mode.

High speed mass production capability.

Reliable machine performance.

User friendly HMI.

Flexible modular design.

Short changeover time.

Long time data traceability.

MES Traceabilitys.

Outstanding quality control: CCD inspection & CFM sensor.

Excellent compatibility.

Compatible with third-party data (such as MES, SCADA) interface.

Real-time equipment performance and process data.

Easy-to-manage part number list.

Standardized and modular design, such as: standard Housing insertion, crimping, CCD modules.

Crimping Module (C202)

Servo-controlled press assures best crimping result.

Integrated with independent crimping force monitoring unit.

Maximum 12 crimping stations could be applied.

Crimping parameters, e.g., crimping height, could be set, adjusted and displayed at HMI.

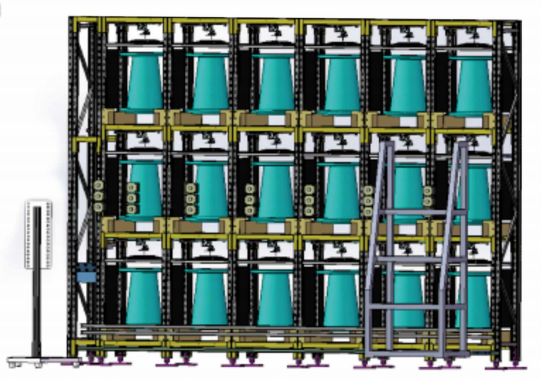

Wire Wall

Three-dimensional cable storage system saves factory floor space dramatically.

Wire Selector

Compatible for maximum 50 different wires works synchronously.

Tool-free quick guide tube changeover 0.13-4mm²(AWG26-11).

Cutting and Stripping Module

Applying double high-speed blades(V-shape/R-angle blade).

Adjust stripping data with HMI to achieve ultra precision and clean stripping.

Cutting & stripping variety of cross-section wires without complicate change-over step.

Untwisting Module

Remove wire twists.

Decline scrap rate.

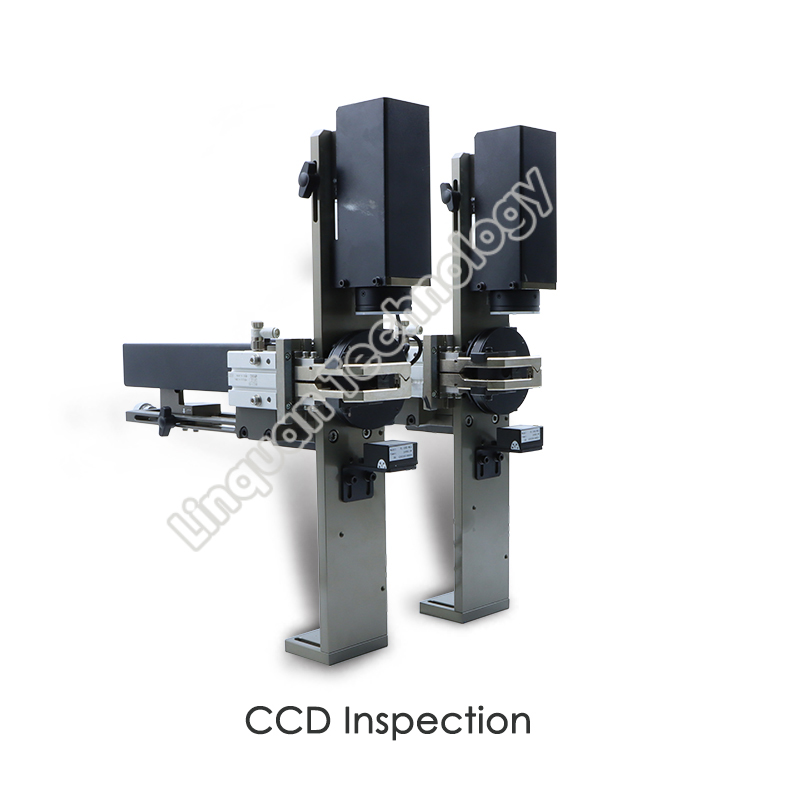

CCD Visual Inspection (TDVM-1)

Integrated QC module, efficient quality monitoring.

Stripping, crimping and center conductor inspection.

Real-time monitoring producing process.

In time detecting scraps.

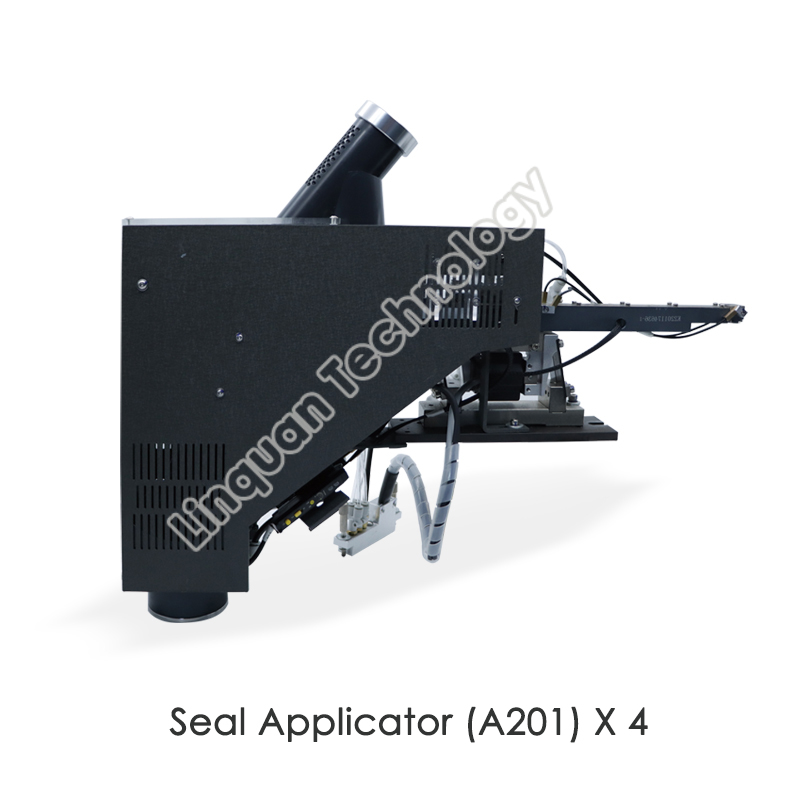

Seal Station (STA201)

Max 6 seal stations configuration.

Latest smaller, optimized module design for versatile machine configuration.

Innovative centralized seal feeding technology, efficiency and capital investment of sealing to wire have been significantly optimized.

Centralized pre-feeding module S201 makes maximum 4 seal applicators A201 together with maximum 8 magazines work synchronously.

Creative seal magazine model M201 design achieves compact dimensions of seal feeder and change-over time optimization.

Centralized Pre-feeding Module S201

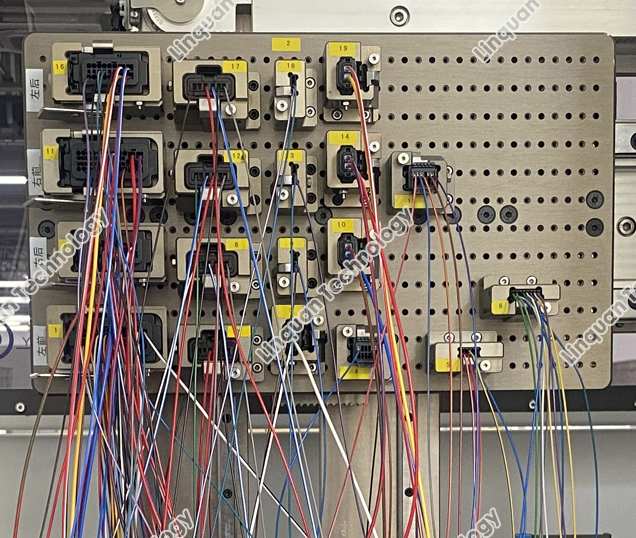

Wire Storage Unit

30 storage positions.

Optimize insertion sequence: from left to right, button to top.

Breakthrough insertion limitations.

Special design for sophisticate wire harnesses.

Insertion Module

Dual insertion clamps structure, ensuring insertion accuracy, stability and efficiency.

Segmented insertion process, integrated insertion and pull-back force detection, declining scrap rate.

Plate-loop Conveying Connector Loading Module

Equipped with two conveying plates, efficient connector reloading.

Versatile connectors loading synchronously.

Enable sequence product producing.

Quick & easy manual final product unloading.