April 13, 2023 Munich Shanghai Electronic Production Equipment Exhibition

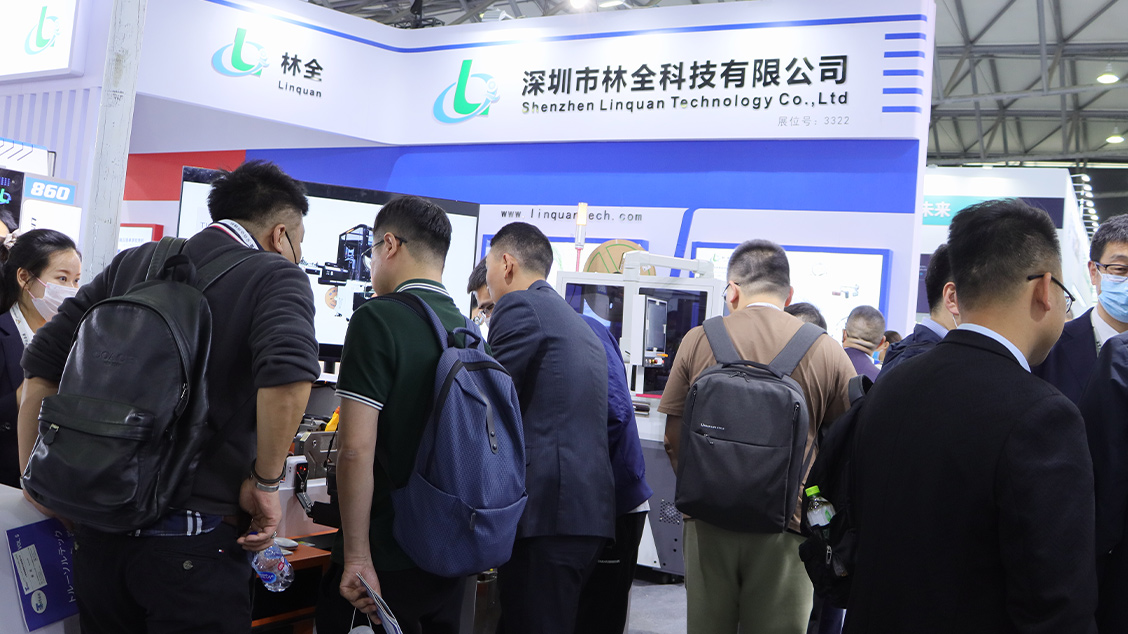

From April 13th to 15th, 2023 Shanghai Productronica successfully completed. The exhibition attracted 822 exhibitors and presented innovative solutions for electronic manufacturing to 70,833 visitors from 47 countries in the 73,000-square-meter exhibition hall. After covid pandemic, electronic intelligent manufacturing industry is full of vitality and everything is recovering. With the continuous international interaction and desire for technical communication, the three-day exhibition site was crowded with people. Like the friends who haven't seen each other for a long time, exhibitors and visitors are catching up enthusiastically. Entrepreneurs come to seek business opportunities and cooperation intentions are frequently reached here.

At present, China is entering a critical stage of transformation and upgrading of the manufacturing industry. China's intelligent manufacturing will usher in an "acceleration moment". The intelligent and digital transformation of the manufacturing industry is a new proposition in the new stage of China's intelligent manufacturing. The factories will comprehensively improve the level of segmentation, visualization and intelligence in design, production, management and other procedures, in order to achieve the purpose of improving quality and efficiency.

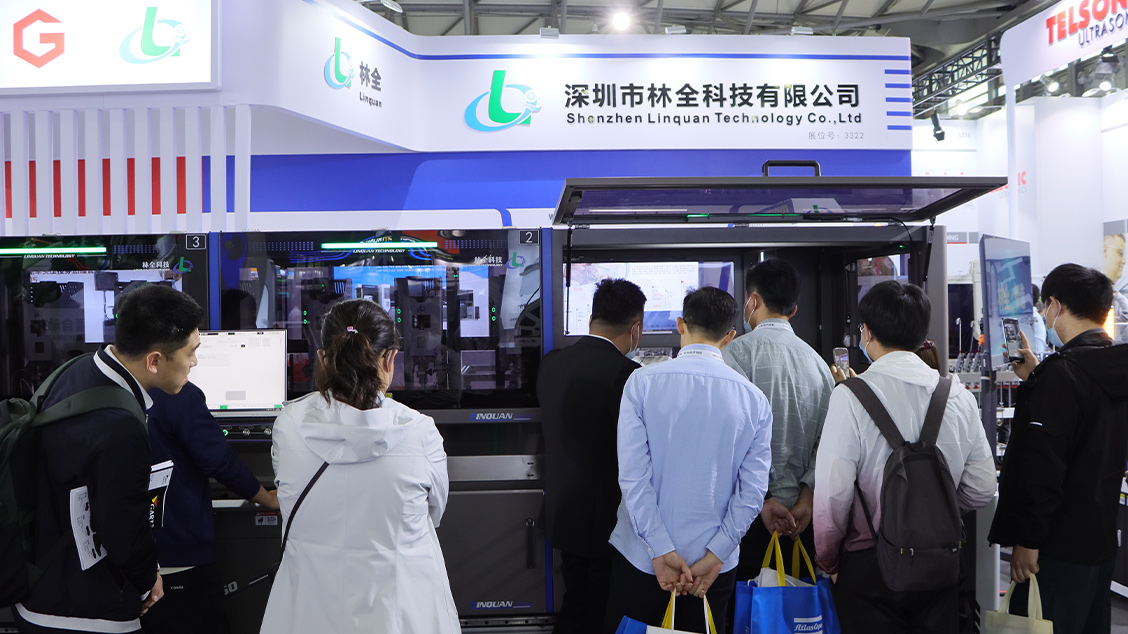

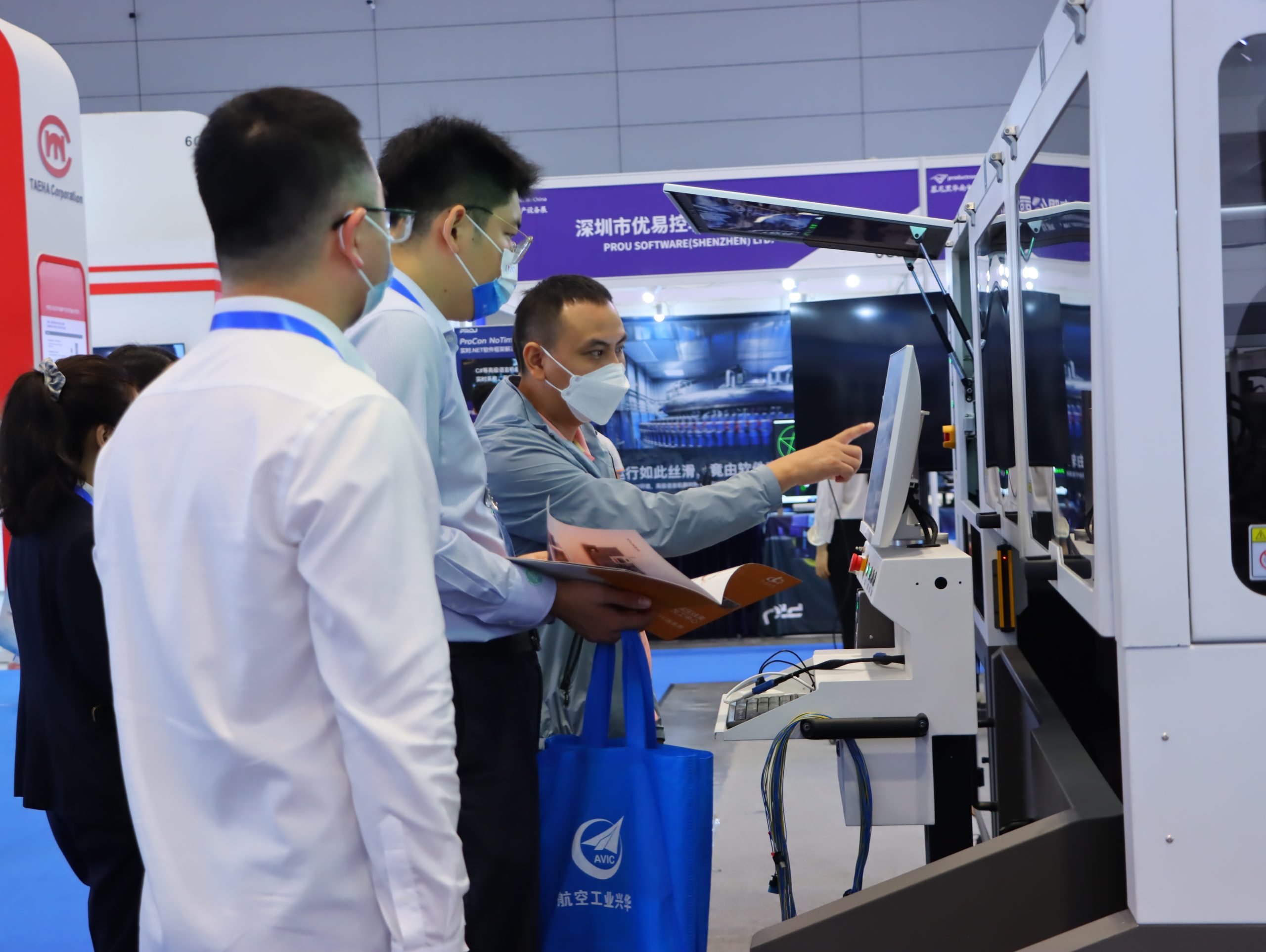

During the exhibition, our company launched the newly developed automatic wire harness processing equipment and automatic production technology. Innovative solutions and strong technical support can help wire harness manufacturers achieve digital, intelligent production and flexible processing.

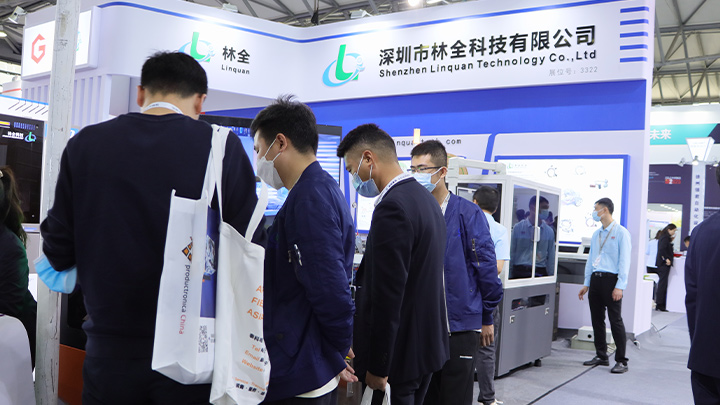

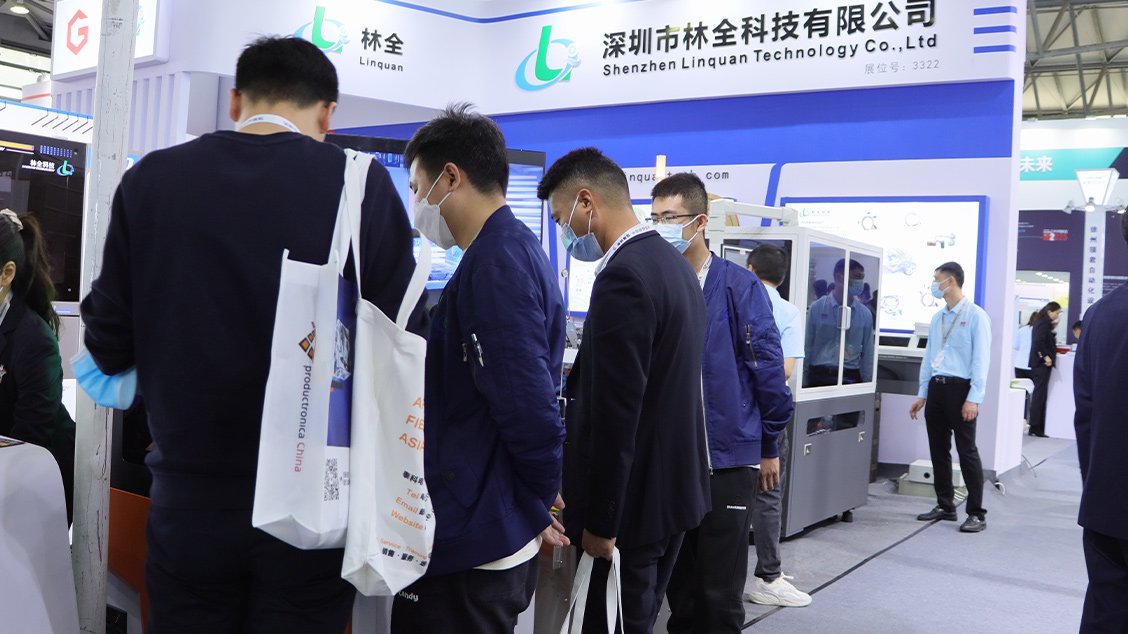

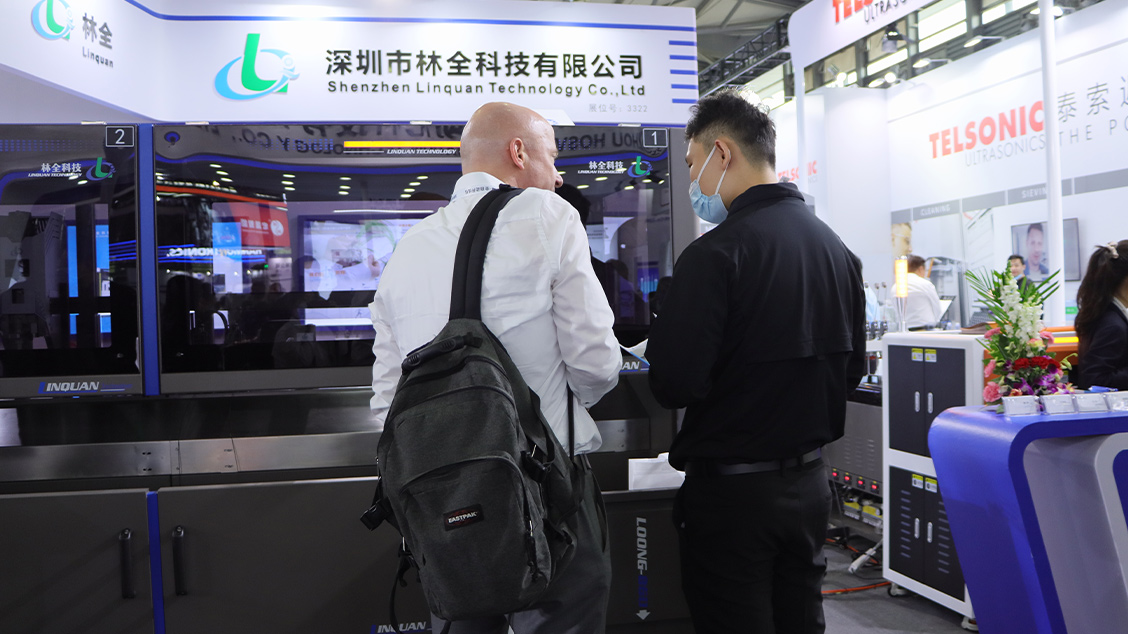

2022 Productronica South China was completed successfully with Linquan Technology attended.

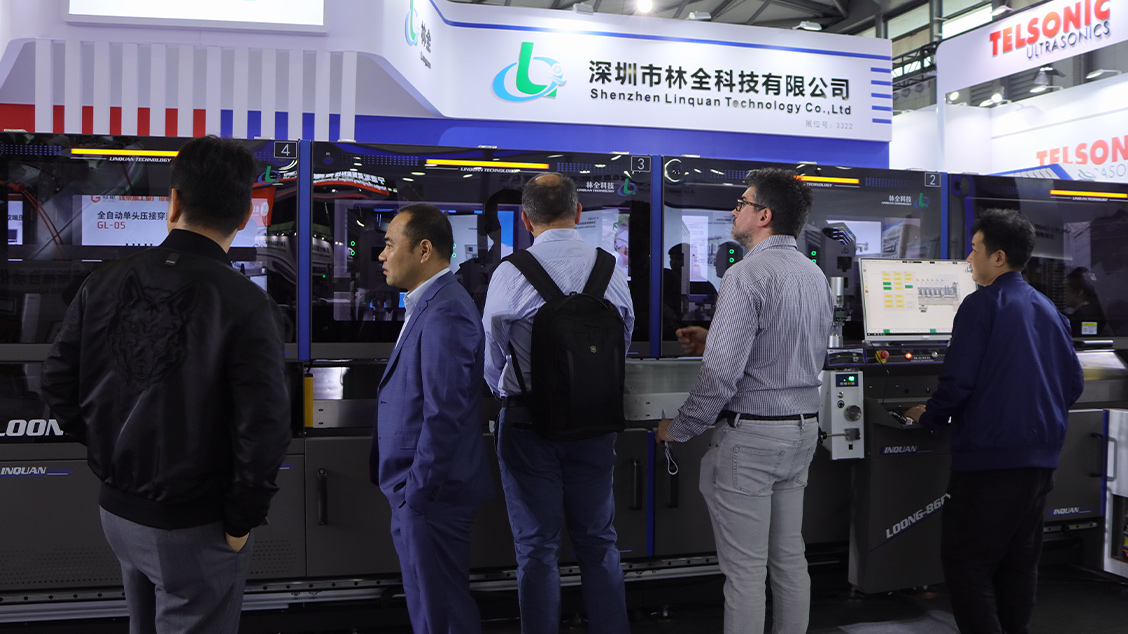

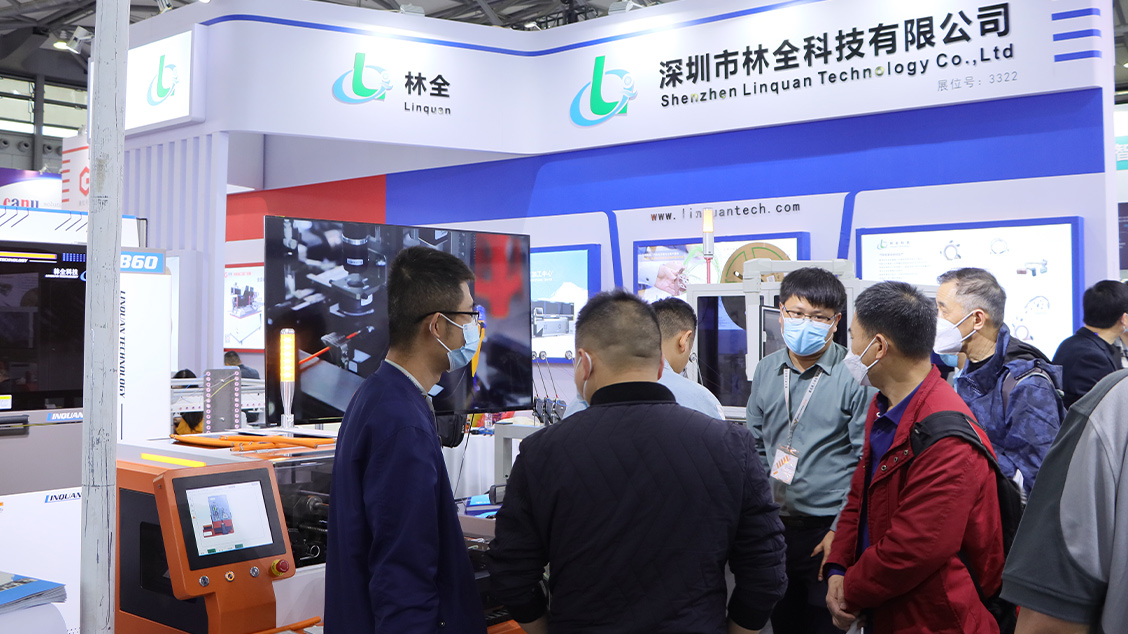

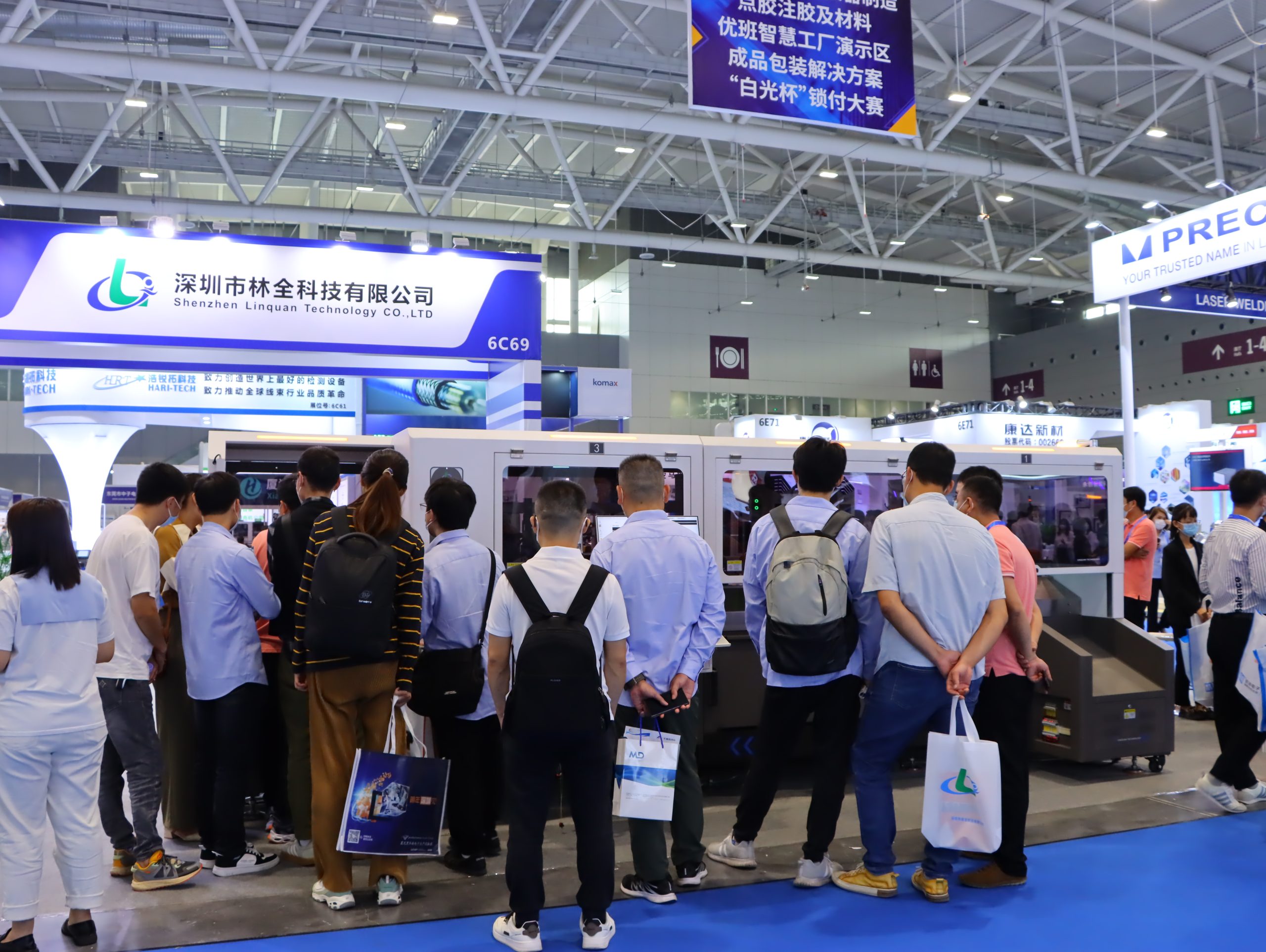

From November 15th to 17th, the 3-day Productronica South China completed successfully. Linquan Technology stood out from exhibitors while recognized by customers and industry professionals.

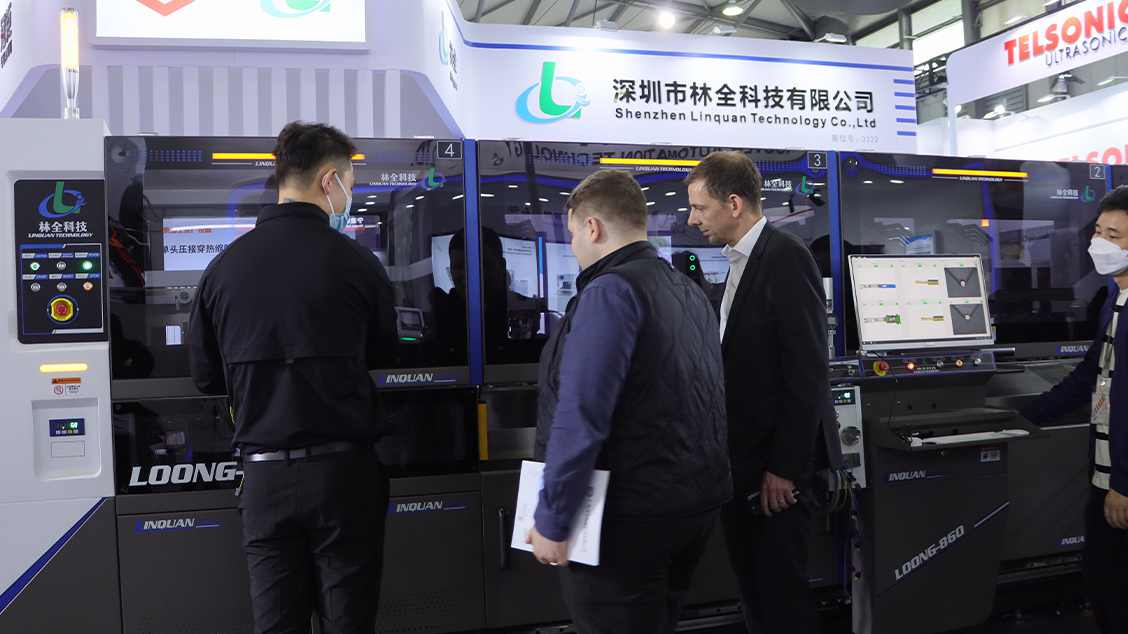

During the exhibition, Linquan Technology showed up with their latest ground-breaking products- Kylin Series HV cable platform and Loong Series LV Wire Harness Processing Center at the 6C69 exhibition booth. A professional team also sent by Linquan to the exhibition site to answer industry related problems for customers and provide market-compliant, innovative and productive solutions.

Dialogue : Building a Smart Factory to Promote the Transformation and Upgrading of the Wiring Harness Industry

Introduction: Recently, on the occasion of the Productronica South China. The exhibition host and the general manager of Linquan Technology Gao Donglin, focused on the trend of "new four modernizations", industry 4.0, the development of wire harnesses and the new products to be exhibited had an in-depth dialogue. The article excerpts highlights from the dialogue.

1、In recent years, the "new four modernizations" of the automotive industry have basically become a consensus. Namely: Software, Intelligent, Electrified, and Connected. Intelligent networks and EV are in golden age. Autonomous vehicles and new energy vehicles destined to be the future Megatrend. As a pioneer of wire harness solution supplier, what efforts have you made in the wire harness industry facing the "new four modernizations" trend?

Gao Donglin:Linquan Technology has an foresight of wire harness industry transformation. Remarkably integrates intelligent systems with traditional processing equipment. Redefines the production mode of automobile wire harnesses manufacturing. The full-automatic HV cable harness manufacturing center, the fully automatic low-voltage wire harness manufacturing center and the MES system developed by us help customers build their core competitiveness. Meanwhile, we also focus on developing technologies for industrial automatize, intelligentize, digitize, and networking. Our business covers automation equipment and industrial software, and provides high-quality, high-efficiency intelligent manufacturing overall solutions for new energy, automotive electronics and other industries.

2、Smart factory is a new stage in the development of industrial 4.0 modern factory informatization. It is based on intelligent technology, digital technology and information technology, through the integration of physical infrastructure and information infrastructure, integrating people, machines, equipment and infrastructure to implement real-time management, coordination and control between multiple systems. It is possible to manage production in a more refined and dynamic way to achieve a "smart" state. So, can you talk about how to use innovative technologies and equipment to build a fully automated smart factory to achieve more optimized performance and more efficient management?

Gao Donglin:The design concept of our Linquan intelligent factory is automation---automatic both-end crimping machine, automatic HV cable harness manufacturing center, automatic low-voltage wire harness manufacturing center;

Networking --- Resource sharing, centralized management, and preparation for Industry 4.0. Linquan adopts intelligent wire harness manufacturing center + factory intelligent management and control system - MES system, to provide digital factory solution;

Digitization 1---Synchronous detection during manufacturing. Linquan is one of the earliest company adopts the CCD inspection system globally within the industry, which compensate for the shortcomings of low reliability and low efficiency of manual detection;

Digitization 2---The production efficiency is greatly improved, and the judgment is synchronized. Linquan developed the crimping force data management system(CFM) to display the detection data through numbers & charts;

Intelligent---Non-stop online detection, improve production efficiency, and reduce HCE in the quality monitoring process.

3、Wire harnesses industry is a very labor-intensive product for OEMs. Each vehicle's wiring harness has thousands of components and the finished product weighs 150lbs or more. Therefore, all the materials and components for these products must be coordinated and shipped around the world. This creates an extremely long, complex supply chain with hundreds of design changes occurring along the way - all of which need to be tracked, implemented and verified individually. So how should the wire harness industry protect its industrial chain and reduce its logistics costs?

Gao Donglin:Lightening is the main tone of future automobile wire harness development. Mainly includes material lightening, structural lightening and layout optimization. In the field of wire harness processing, we focus on layout optimization and intelligent control. Linquan Technology's intelligent wire harness manufacturing line + intelligent management and control system (MES system, digital factory solution) achieves resource sharing and centralized management of wire harness production & supply. Realize long-time data preservation and traceability.

4、What new products are you going to exhibit at this year's Productronica South China? What support and help will these products bring to consumer electronics, automotive electronics, medical electronics, industrial control cabinets and other fields?

Gao Donglin:Linquan will present automatic HV cable processing equipment, automatic both-end insertion machine and Linquan intelligent factory construction plan. Helping wire harness enterprises to build intelligent wire harness manufacturing lines and factory intelligent management systems. Reducing production costs and improve production efficiency & product quality.

5、What do you want to say about China's electronic intelligent manufacturing industry in 2023?

Gao Donglin:In today's society of rapid development and continuous technological innovation, the intelligent manufacturing industry should also keep up with the trend of the times, strengthen the awareness of learning and innovation, continuously improve the technological competitiveness of enterprises, and improve the awareness and ability of self-innovation. At present, mastering the theory and knowledge of science and technology is the best way to face it on the road to intelligent manufacturing in the manufacturing industry. Due to the instability and uncertainty of the economic and social environment, domestic manufacturing enterprises are facing enormous pressure for transformation. They need to shift from low-cost competitive strategies to establish differentiated competitive advantages. They also need to balance production capacity, improve product quality, achieve cost reduction, increase efficiency and continuously shorten the product development & market cycle. Promoting intelligent manufacturing and building a data-driven enterprise has become a necessary means of manufacturing development strategy. Looking forward to 2023, I look forward to the steady progress of China's intelligent manufacturing! Linquan Technology will also keep up with the pace of the times, continue to innovate in the wire harness processing industry, create a fully automatic intelligent wire harness processing system, and use its own actions to realize the intelligent leap of the wire harness processing industry.

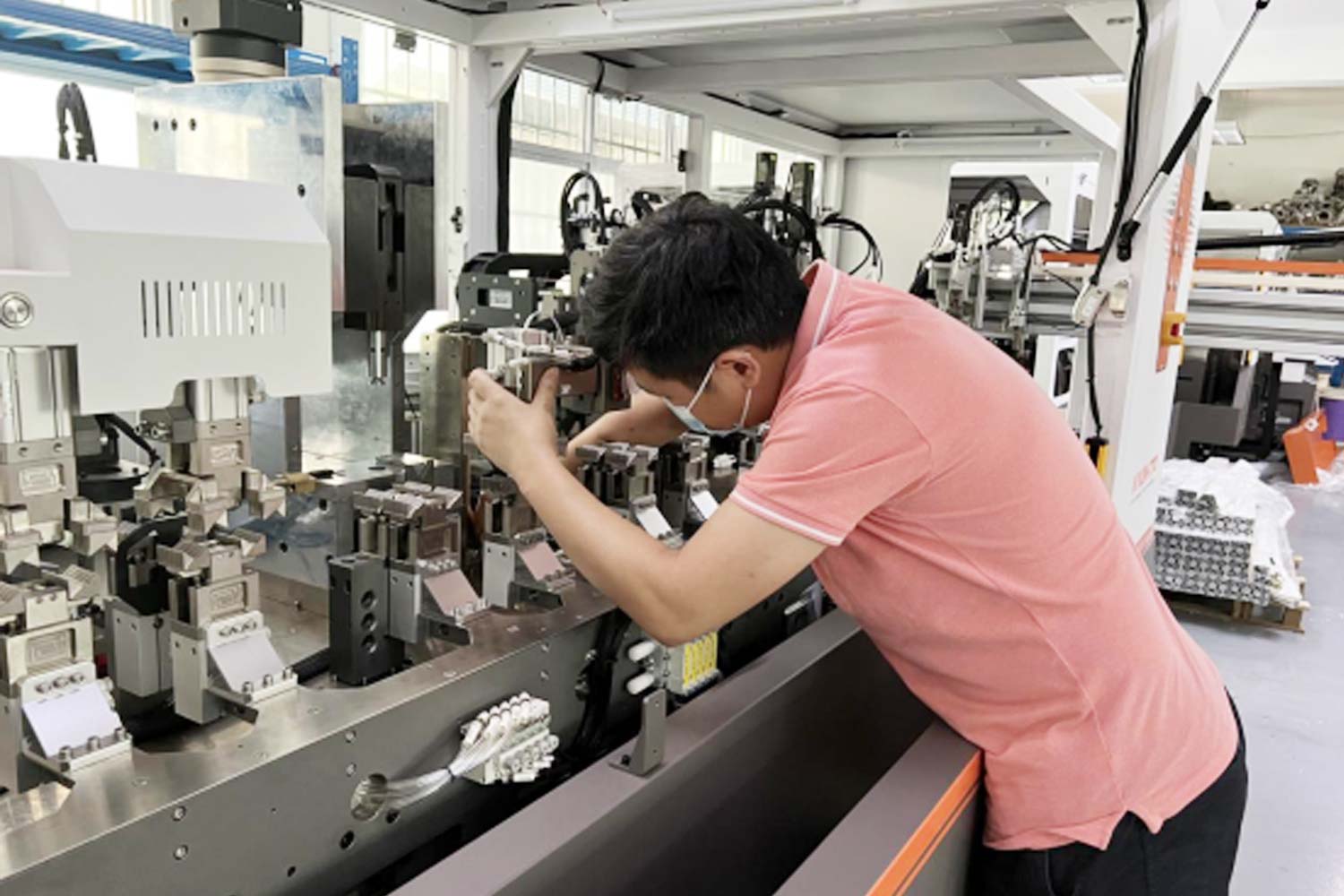

Shenzhen Linquan Technology Co., Ltd. Resumed Work and Production Safely and Orderly

On March 21, Linquan technology returned to work and production and deployment of related work, including set up resumption work leading group and work plan, screen electricity, check fire protection, mechanical and other security risks. And carry out the entry personnel safety education and training and technical clarification, aiming at key link and target tasks; Further organize personnel to resume work in an orderly manner according to key points. Workshops and offices have been comprehensively disinfected, and health monitoring of those returning to work has been strengthened. Supplies for epidemic prevention have been replenished. We have conducted safety education and training for the workers to resume work, and improved the procedures for entering and resuming work, so as to ensure the safety and preparations for the rapid resumption of work.